|

|

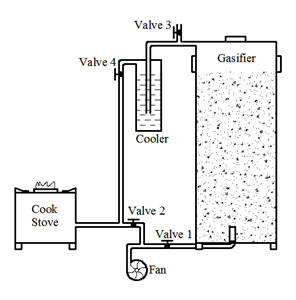

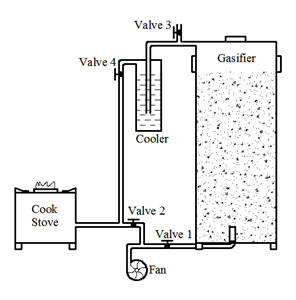

| Figure 1. Schematic diagram of the gasifier system | Photo 1. The gasifier stove in operation |

| Livestock Research for Rural Development 28 (5) 2016 | Guide for preparation of papers | LRRD Newsletter | Citation of this paper |

The air-flow in an updraft gasifier stove charged with rice husk or sawdust was varied from 2.64 to 4.13 m3/h.

The temperature in the combustion zone and the content of hydrogen and carbon monoxide in the gas increased with increasing airflow. In contrast, the yield of tar and of biochar decreased. Biochar yield was higher when rice husk was the feedstock compared with sawdust.

Key words: biomass, carbon monoxide, carbon sinks, climate change, global warming, hydrogen, pyrolysis, soil carbon, temperature

Most climate scientists agree that the most important strategy for reducing global warming is to restore the biosphere’s ability to store soil carbon (Goreau 2014). Producing biochar from vegetative biomass and applying it to the soil is considered to be the most practicl way to achieve this purpose, as biochar applied to soil has proved to be an effective sink for sequestering carbon dioxide (Lehman and Joseph 2014). Biochar is produced by carbonization of organic matter at high temperatures and in a restricted flow of oxygen. The yield of biochar when biomass is carbonized depends on the mode of carbonization (Table 1). The yield of biochar is highest with slow carbonization but it is accompanied by a high proportion of liquids (bio-oil) and a low proportion of gas (syngas). The yield of biochar is lower with gasification but in this case the products are more easily utilized, as the gas can be used for cooking and heating (Olivier 2010) or to replace fossil fuels used in boilers, engines and fuel cells (Sang Jun Yoon et al 2012).

|

Table 1. Product yield from pyrolysis (or gasification) of wood (expressed as yield in terms of % dry weight conversion to products) (from Bridgewater 2007) |

||||

|

Mode |

Conditions |

Liquid |

Biochar |

Gas |

|

Fast |

Moderate temperature (around 500ºC). Short hot vapor residence time ~1 second |

75% |

12% |

13% |

|

Intermediate |

Moderate temperature (around 500ºC). Moderate hot vapor residence time ~ 10-20 seconds |

50% |

20% |

30% |

|

Slow (carbonization) |

Low temperature (around 400ºC). Very long solids residence time |

30% |

35% |

35% |

|

Gasification |

High temperature (around 800ºC). Long vapor residence time |

5% |

10% |

85% |

In the Vietnamese situation, small scale gasification systems have advantages in that they can be applied, and the products used, in rural areas. Thus the present study aimed to determine the effects on the products of gasification, especially the yield of biochar, of increasing the air-flow in a small scale updraft gasifier stove charged with either rice husk or wood sawdust.

The experiments were conducted in the Renewable Energy Laboratory, Nong Lam University, Ho Chi Minh, Vietnam, from July 2014 to March 2015.

|

|

| Figure 1. Schematic diagram of the gasifier system | Photo 1. The gasifier stove in operation |

The gasification system comprises a combustion chamber, a variable speed air-blower, a water-cooling chamber and the stove for burning the gas (Figure 1; Photo 1).

The feedstocks (Table 2) were rice husk from a rice mill located in Long An province in the Mekong Delta and sawdust from a furniture company located in Binh Duong province in Southeast Vietnam.

The rate of air flow was varied from 2.64 m3/h to 4.13 m3/h with rice husk feedstock and from 2.47 m3/h to 4.02 m3/h with sawdust.

|

Table 2. Proximate and ultimate analysis of the rice husk and sawdust |

||

| Rice husk | Sawdust | |

|

Proximate analysis (wt. %) |

||

|

Moisture |

10.9 |

8.6 |

|

Volatile matter |

51 |

70.7 |

|

Ash |

18 |

0.8 |

|

Fixed carbon |

20.1 |

19.9 |

| Ultimate analysis (wt. %) | ||

|

Carbon |

34.6 |

50.7 |

|

Hydrogen |

4.23 |

5.71 |

|

Nitrogen |

0.46 |

0.57 |

|

Oxygen |

31.7 |

41.9 |

|

Heating value (kcal/kg DM) |

3961 |

4749 |

| Source: Le Duc Dung and Vu Van Nam 2014; Nguyen Tien Cuong et al 2015 | ||

A portable infra-red syngas analyzer (Gasboard 3100P, Wuhan Cubic Optoelectronics Co, Ltd) was used for simultaneous measurement of the concentrations of CO, CO2, CH4, H2 and O2 in the syngas and for calculation of the heating value.

|

|

| Photo 2. The gasboard 3100P syngas analyzer | Photo 3. The gasboard 3100P syngas analyzer |

Linear equatons were fitted to the data using the Excel program in the Microsoft Excel software. The fixed "X" variable was the air-flow; the dependent variables were concentrations of hydrogen, carbon monoxide, tar and biochar.

The temperature of the gas in the reduction zone increased linearly with the rate of air-flow with higher values for rice husk than for sawdust (Figures 2a and 2b).

|

|

| Figure 2a. Effect of air-flow on the temperature of the gas with rice husk |

Figure 2b. Effect of air-flow on the temperature of the gas with sawdust |

The average content of hydrogen in the gas was higher for sawdust feedstock than for rice husk; in contrast, the proportion of carbon dioxide was lower for sawdust than for rice husk. There were tendencies for the concentration of both gases to incease slightly with increasing rate of air-flow (Figures 3a and 3b).

|

|

| Figure 3a. Effect of air-flow on the composition of the gas with rice husk |

Figure 3b. Effect of air-flow on the composition of the gas with sawdust |

There was a marked decrease in the tar content of the gas as the rate of air flow was increased (Figures 4a and 4b. The rate of decrease in the tar content was greater for the rice husk substrate than for the sawdust.

|

|

| Figure 4a. Effect of air-flow on the tar content of the gas with rice husk |

Figure 4b. Effect of air-flow on the tar content of the gas with sawdust |

Much more biochar (about 60%) was produced from rice husk than from sawdust (Figures 5a and 5b), the quantities decreasing with increasing rate of air-flow and temperature.

|

|

| Figure 5a. Effect of air-flow on the production of biochar from rice husk |

Figure 5b. Effect of air-flow on the production of biochar from sawdust |

The effects on the yield and composition of the gas by increasing the air-flow were mainly the result of the increased temperature inside the gasifier. This has been amply demonstrated in other studies on gasification of a wide range of feedstocks (Bui Trung Thanh 2012; Antonopoulos et al 2012; Roy et al 2013; Nsamba et al 2014).

From the point of view of global warming, the important issue is the yield of biochar. which is considered to be the most approriate sink for atmospheric carbon (Lehmann and Joseph 2014). However, most studies on gasification do not mention the yield of biochar (eg: Puig-Arnavat et al 2010; Sang Jun Yoon et al 2011; Roy et al 2013). Biochar has been studied as an absorbent for the tar that is an undesired contaminat in syngas (Shen 2015). However, as the value of biochar as a soil amendment appears to be a funcion of the surface area (Lehmann and Joseph 2014), its value after absorbing the tar would be considerably reduced.

The results of our study indicate that biochar yield decreases with increasing rate of air-flow which in turn increases the operating temperature, and the proportions of hydrogen and carbon monoxide in the syngas. There is thus an inverse relationship between gas composition and biochar yield. From the point of view of mitigating global warming, it would seem that optimizing biochar yield has a greatger priority than the yield of syngas. The higher yield of biochar from rice husk compared with sawdust would thus appear to be an advantage of the former. On the other hand we have no data on the relative value as soil amendment of the biochar from rice husk compared with that from sawdust. The higher content of silica in the rice husk is another factor which needs to be considered.

Bridgewater T 2007 Pyrolysis of biomass. IEA Bioenergy:1:T34:2007:01 http://www.nuclearethanol.com/library/pyrolysis/Biomass%20Pyrolysis.pdf

Bui Trung Thanh 2012 Practical research determines main parameters which influence operation of the small scale gasifier. Journal of Science and Technology (University of Danang) 9 (58) 83-91

Goreau T J 2014 Global biogeochemical restoration to stabilize CO2 at safe levels in time to avoid severe climate change impacts to Earth’s life support systems: Implications for the United Nations Framework Convention on Climate Change, in T. J. Goreau, R. G. Larson, & J. A. Campe (Editors), 2014, Geotherapy: Innovative Technologies for Soil Fertility Restoration, Carbon Sequestration, and Reversing Atmospheric CO2 Increase, CRC Press J

Lehmann J and Joseph S (Editors) 2015 (2nd Edition) Biochar for Environmental Management. Taylor and Francis. http://www.biochar-international.org/projects/book

Nsamba H K, Hale S E, Cornelissen G and Bachmann R T 2014 Improved gasification of rice husks for optimized biochar production in a top-lit updraft gasifier. Journal of sustainable bioenergy systems. Volume 4, 225-242 http://www.scirp.org/journal/jsbs

Olivier P 2010 Small scale production of food, fuel. feed and fertilizer from recycled waste s. Livestock production, climate change and resource depletion. International Conference, Pakse, Laos http://mekarn.org/workshops/pakse/html/olivier.docx

Puig-Arnavat M, Bruno J C a. Internaational Journal of nd Coronas A 2010 Review and analysis of biomass gasification models. Renewable and Sustainable Energy Reviews . Volume 14, Issue 9, December 2010, Pages 2841–2851

Roy P C, Datta A and Chakraborty N 2013 An assessment of different biomass feedstocks in a downdraft gasifier for engine application. Fuel 106: p. 864-868.

Sang Jun Yoon, Yung-Il Son, Yong-Ku Kim, Jae-Goo Lee 2012 Gasification and power generation characteristics of rice husk and rice husk pellet using a downdraft fixed-bed gasifier . Renewable Energy 42: 163-167.

Shen Y 2015 Chars as carbonaceous adsorbents/catalysts for tar elimination during biomass pyrolysis or gasification. Renewable and Sustainable Energy Reviews . Volume 43, pp 281–295 http://www.sciencedirect.com/science/article/pii/S1364032114010004

Lê Đức Dũng and Vũ Văn Nam 2015. Nghiên cứu phát triển bếp đun khú hóa trấu cải tiến nhằm nâng cao hiệu suất, giảm phát thải khí CO và bụi. Tạp chí Năng Lượng Nhiệt (Thermal Energy Review) 125: 11-15. (In Vietnamese)

Nguyen Tien Cuong, Pham Hoang Luong and Van Dinh Son Tho 2014. A study effect of moisture content of biomass on energy performance of downdraft gasifier. Thermal Energy review 120: 10-14. (In Vietnamese)

Received 14 March 2016; Accepted 6 April 2016; Published 1 May 2016