Cassava pulp as livestock feed; effects of storage in an open pit

Phanthavong Vongsamphanh, Viengsakoun Napasirth1, Sangkhom Inthapanya2 and T R Preston3

Department of Livestock and Fisheries, Ministry of Agriculture and Forestry

PO Box 6644 Vientiane, Lao PDR

ptvkivor@yahoo.com

1Faculty of Agriculture, National University of Laos, Nabong Campus, P.O.Box 7322, Vientiane, Lao PDR

2Souphanouvong University, Luang Prabang, Lao PDR

3Center for Research and Technology Transfer, Nong Lam University, Ho Chi Minh City, Vietnam

Abstract

Samples were taken from an uncovered pit (250*50m area; 7 m deep) in

which cassava pulp, the byproduct from cassava root starch extraction, had been

stored over a 4 year period (2011-14). A sample taken at 2.5m depth was

incubated with urea, cassava leaf meal and rumen fluid in an in vitro

rumen fermentation and compared with fresh cassava root as a control.

The upper 50 cm had rotted due to exposure to air and rain, but samples from

0.5 to 7m revealed that these were satisfactorily ensiled with pH values in the

range 3.2 to 3.5. Gas production amd DM mineralization values after 24h

incubation of the sample taken at 2.5m depth indicated that the pulp was only

slightly inferior (<9%) to fresh cassava root as an energy feed resource for ruminants.

Key words: cassava root, cattle feed, gas production, pH, methane, starch processing

Introduction

The Lao-Indochina Group Public Company at Nashaw village, Pakngum District,

Vientiane, processes up to 100.000 tonnes per year of

cassava roots into starch for export. During the 6-7 month harvest

season from October to March-April (the dry season in Lao PDR) this amounts

to 480 tonnes of roots daily. The byproduct remaining after starch

extraction, known as cassava pulp, represents from 10 to 15% of the original

weight of fresh roots (Sriroth et al 2000). Over the past 4 years, very little of

the cassava pulp was bought by farmers and almost all of it had

been stored in a pit adjacent to the factory, which had not been covered or protected in any way.

As the first step in a study to evaluate the potential feeding value of the

stored pulp, the site was visited on July 10, 2014. As the pit was not

covered, the upper surface of the stored material had rotted due to

accumulation of rain falling during the wet season (Photo 1). However, A

sample taken at a depth from the surface of 50 cm was perfectly ensiled with

a pH of 3.5.

|

|

| Photo 1. The pit containing the cassava pulp; photo

taken in the rainy season |

Photo 2. Taking the samples in the pit |

|

|

| Photo 3. Inserting the PVC tube to reach the

bottomof the pit |

Photo 4. Separating the samples from the core taken

from the PVC tube |

It was hypothesized that if the rest of the pulp in the pit had similar

characteristics to the observed sample then it would be a suitable basal

diet for the intensive fattening of cattle, for which there is an attractive

market (>USD 2.00/kg live weight) in Lao PDR for export to China, Thailand

and Vietnam.

Materials and methods

Testing the pH and dry matter content of the pulp over the whole range of

depth (0.5 to 7.0m)

Further tests were done on 16 July taking consecutive samples as far as the

bottom of the pit using a 10cm diameter PVC tube 8m long (Photo 2). The pH and the DM

content were determined by standard methods (AOAC 1990).

In vitro gas and methane production

A sample of the ensiled cassava pulp was taken at 2.5m depth to determine in

vitro gas production according to the method developed by Sangkhom et al (2011).

The sample had a pH of 3.5. In the in vitro test it was compared with

fresh whole cassava root. Urea and cassava leaf meal were added to both

substrates (Table 1). There were two replicates of each of the treatrments

(cassva root vs cassava pulp).

|

Table 1.

Proportions of the substrates in the

in vitro incubation

|

|

|

DM basis, %

|

Fresh substrate, g

|

|

|

Cassava root

|

Cassava pulp

|

Cassava root

|

Cassava pulp

|

|

Fresh cassava root

|

67.0

|

|

26.8

|

|

|

Cassava pulp

|

|

67

|

|

28.7

|

|

Urea

|

3.0

|

3.0

|

0.4

|

0.4

|

|

Cassava leaf meal

|

30.0

|

30.0

|

4

|

4

|

|

Total

|

100

|

100

|

27.2

|

29.1

|

Fresh cassava root was purxhased from the market and

chopped into small piece around 1-2 cm of length, then ground (1mm sieve) by machine.

The cassava leaf was collected in the farm of Souphanouvong University; Luang

Prabang and chopped into small pieces around 1-2 cm, then dried in an oven at

100°C for 24h and ground (1mm sieve) by machine.

Representative samples of the substrates (12 g DM) were

put in each incubation bottle, after which were added 0.96 liters of buffer

solution (Table 2) and 240 ml of rumen fluid (obtained from a recently

slaughtered buffalo in the local abattoir), prior to filling each bottle with

carbon dioxide. The bottles were incubated at 38ºC in a water bath for 24h.

|

Table 2. Ingredients of the buffer solution

|

|

Ingredients

|

CaCl2

|

NaHPO4.12H2O

|

NaCl

|

KCl

|

MgSO4.7H2O

|

NaHCO3

|

Cysteine

|

|

(g/liter)

|

0.04

|

9.30

|

0.47

|

0.57

|

0.12

|

9.80

|

0.25

|

|

Tilly and Terry (1963).

|

Gas production was measured from 0-6h, 6-12h, 12-24h.

Methane was measured in the gas from the 12-24h collection using a Crowcom

infra-red meter.

Statistical analysis

Data for gas prodution and methane in the gas were

analysed by the GLM option in the ANOVA program of the Minitab (2010) sotfware.

Sources of variation were treatments, replicates and error. Regression equations

were derived using Microsoft Excel software.

Results and discussion

All samples taken from the pit had a consistent pH below 3.5 and appeared to

be perfectly stable as silage (Figures 1 and 2). Due to compression of the

pulp inside the tube, as this was forced to the bottom of the pit, the

recovered samples most probably represented material over the whole range of

depth of 0.5 to 7.0m. It is also probable that the true DM content is

between 20 and 25%. This can only be checked when the full face of the pit

is opened.

|

|

|

Figure 1. Changes in dry matter content of

the pulp at increasing depth in the pit

|

Figure 2. Changes in pH of the pulp at

increasing depth in the pit

|

|

Table 3.

Mean values for gas production, methane in the gas and DM

mineralized in the in vitro incubation of cassava pulp and

cassava root supplemented with urea and cassava leaf meal

|

|

|

Cassava pulp

|

Cassava root

|

SEM

|

p

|

|

Gas production, ml

|

|

|

|

|

0-6h

|

365

|

385

|

14.1

|

0.5

|

|

6-12h

|

775

|

840

|

10.6

|

0.14

|

|

12-24h

|

835

|

960

|

17.7

|

0.12

|

|

Total

|

1975

|

2185

|

42.3

|

0.18

|

|

CH4, %

|

23.5

|

25.5

|

2.12

|

0.63

|

|

DM mineralized,%

|

66.5

|

67.3

|

0.53

|

0.38

|

|

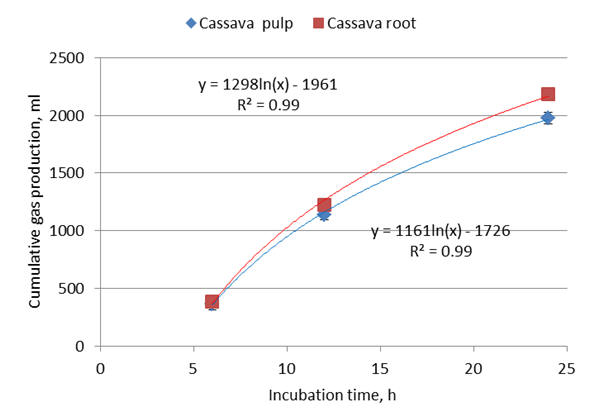

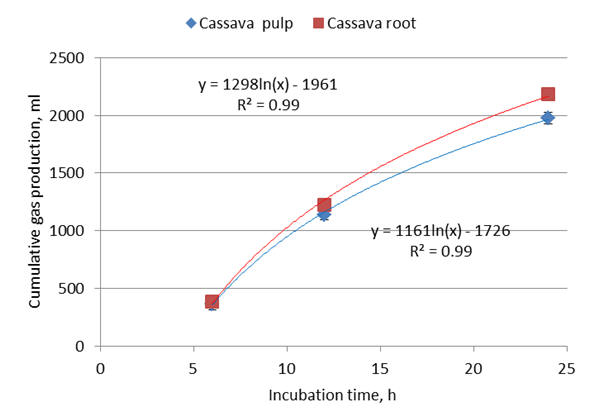

| Figure 3. Gas production from cassava pulp and

cassava root supplemented with urea and cassava leaf meal |

Total gas production over 24 h tended (p <0.18) to be less with the pulp than with the

whole cassava root (Table 2; Figure 3), however, the overall diference was

only 9% ; there were no differences in DM mineralized which were

less than 1% during this period. Thus it can be expected that the energy

feed value of the ensiled pulp will be only slightly less than that of the

whole fresh root. The methane content of the gas produced between 12 and 24h

did not differ between the pulp and

root samples.

The crude protein in cassava pulp is very low. Reported values are 1.55 to

2.6% in DM (Sriroth et al 2000; Suksombat et al 2007). However, it is rich

in starch; 69% in DM according to Sriroth et al (2000). This makes it suitable as the energy

component of an intensive feeding system for fattening cattle. It would need

to be supplemented only with urea, a source of roughage and bypass protein

and minerals, as has been demonstrated for other low-protein,

carbohydrate-rich tropical feeds such as molasses (Preston 1971; Ffoulkes

and Preston 1978))and sugar cane (Preston et al 1976).

Conclusions

- Cassava pulp was ensiled naturally (pH 3.5) when stored in an uncovered pit

for up to 4 years.

- Gas production amd DM mineralization values after 24h fermentation in an

in vitro incubation showed it to be only slightly inferior (<10%) to

fresh cassava root as an energy feed resource for ruminants.

References

AOAC 1990

Official methods of analysis. 15th ed. AOAC, Washington, D.C.

Ffoulkes

D and Preston T R 1978 Cassava or

sweet potato forage as combinedsources of protein and roughage in molasses based

diets: effect of supplementation with soybean meal. Tropical Animal Production,

Voume 3, Number 3 pp186-192

http://www.utafoundation.org/UTAINFO1/TAP/TAP33/3_3_1.pdf

Inthapanya S, Preston T R and Leng R A 2011 Mitigating methane

production from ruminants; effect of calcium nitrate as modifier of the

fermentation in an in vitro incubation using cassava root as the energy source

and leaves of cassava or Mimosa pigra as source of protein. Livestock Research

for Rural Development. Volume 23, Article #21.

http://www.lrrd.org/lrrd23/2/sang23021.htm

Minitab 2010 Minitab

Statistical Software, Release 16.1.1 for Window. (Minitab

Inc. State College PA, USA)

Preston T R 1971

Quantitative aspects of animal protein

production from NPN in ruminants Source:FAO/IAEA.

Tracer studies on non-protein nitrogen for ruminants.

publications\Preston1971(IAEA).pdf

Preston T R, Carcaņo C, Alvarez F J and Gutierrez D G

1976 Rice polishings as a supplement

in a sugar cane diet effect of level of rice polishings and of processing the

sugar cane by derinding or chopping. Tropical Animal Production. Volume 1,

Number 3 pp 1-14

http://www.utafoundation.org/UTAINFO1/TAP/TAP13/1_3_1.pdf

Sriroth K, Chollakup R, Chotineeranat S, Piyachomkwan K and Oates C

G 2000 Processing of cassava waste for improved biomass

utilization. Bioresource

Technolology 71(1):63-69.

Suksombat W, Lounglawan P and Noosen P 2007 Energy and protein evaluation of five feedstuffs used in diet in which cassava pulp as main energy source for lactating dairy cows. Suranaree Journal of Science and Technology Volume 14, Number 1, pp 99-107

Tilley J M A and Terry R A 1963 A two stage technique for the in vitro digestion of forage crops. Journal of the British Grassland Society 18 : 104.

Received 25 August 2014; Accepted 29 August 2014; Published 5 September 2014

Go to top